Tournevis

The best screwdrivers have shafts made from good-quality steel, and handles of tough moulded plastic.

Buy a tool with a reputable brand name. Cheap tools with brittle plastic handles can be dangerous, as they may break under pressure.

Use a screwdriver with a blade that fits exactly into the screw slot - if it is flat-bladed it should be no wider than the slot. If the blade is ill-fitting, the tool is more likely to slip or open out the screw head. Keep flat blades ground square, with the edge evenly tapered.

A very tight screw can sometimes be shocked loose by tapping the end of the screwdriver with a hammer. A few drops of penetrating oil and a firm tap may free a rusted screw.

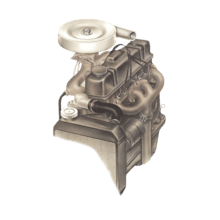

Engineer's screwdriver

Strong-shafted engineer's screwdrivers are designed for heavy mechanical work. The longer the shaft and the thicker the handle, the greater the turning effort that can be applied.

The blades may be flat to fit into a straight (or plain) slot screw, or cross-headed (such as Phillips or Pozidrive) to fit into a cross-slot screw. Use the correct type of cross-head for the screw, or its slot may be damaged.

Shafts generally range in length from about 100 to 300mm plain, or 80-200mm cross-head. Shafts may be squared or have a hexagonal shoulder at the base so that a spanner can be fitted to help with stubborn screws.

Chubby screwdriver

Short-handled, short-shafted chubby or stubby screwdrivers are designed for use in confined spaces. Some have handles that can be fitted with a T-bar to give extra leverage.

Shafts are generally about 35-38mm long, and both flat-head or cross-head blades are available.

Angle screwdriver

Angle, right-angle or offset screwdrivers are useful for reaching screws in awkward positions. They are generally 5 to 6in. long. Normally, angle screwdrivers have a blade at each end; both may be the same type - flat or cross-head - or there may be one end of each type

A screwdriver is a tool, manual or powered, for turning (driving or removing) screws. A typical simple screwdriver has a handle and a shaft, and a tip that the user inserts into the screw head to turn it. The shaft is usually made of tough steel to resist bending or twisting. The tip may be hardened to resist wear, treated with a dark tip coating for improved visual contrast between tip and screw—or ridged or treated for additional 'grip'. Handle are typically wood, metal, or plastic and usually hexagonal, square, or oval in cross-section to improve grip and prevent the tool from rolling when set down. Some manual screwdrivers have interchangeable tips that fit into a socket on the end of the shaft and are held in mechanically or magnetically. These often have a hollow handle that contains various types and sizes of tips, and a reversible ratchet action that allows multiple full turns without repositioning the tip or the user's hand.

A screwdriver is classified by its tip, which is shaped to fit the driving surfaces—slots, grooves, recesses, etc.—on the corresponding screw head. Proper use requires that the screwdriver's tip engage the head of a screw of the same size and type designation as the screwdriver tip. Screwdriver tips are available in a wide variety of types and sizes (List of screw drives). The two most common are the simple 'blade'-type for slotted screws, and Phillips.

A wide variety of power screwdrivers range from a simple 'stick'-type with batteries, a motor, and a tip holder all inline, to powerful "pistol" type VSR (variable-speed reversible) Cordless drills that also function as screwdrivers. This is particularly useful as drilling a pilot hole before driving a screw is a common operation. Special combination drill-driver bits and adapters let an operator rapidly alternate between the two. Variations include impact drivers, which provide two types of 'hammering' force for improved performance in certain situations, and "right-angle" drivers for use in tight spaces. Many options and enhancements, such as built-in bubble levels, high/low gear selection, magnetic screw holders, adjustable-torque clutches, keyless chucks, 'gyroscopic' control, etc., are available.

Read more on Wikipedia

Cet outil est utilisé dans

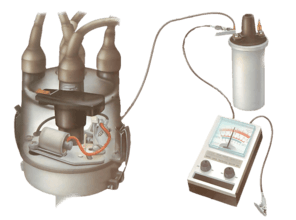

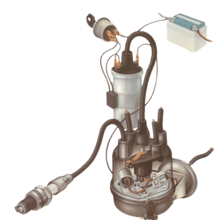

Lors de la pose de nouveaux points de contact dans le distributeur, la façon normale de vérificat...

If testing the starter circuit (See Checking the starter circuit) indicates a fault in the starte...

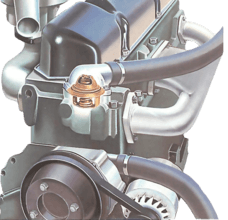

If the engine warms up very slowly, or never reaches normal temperature, or if it overheats quick...

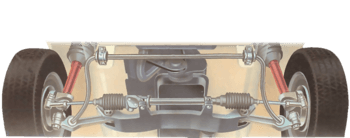

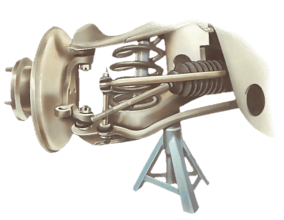

Presque toutes les articulations et pivots dans un système de suspension moderne sont en caoutch...

Speedometer failure is likely to be caused by a fault in the cable that runs from the gearbox to...

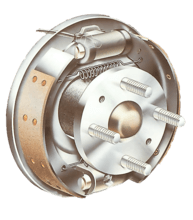

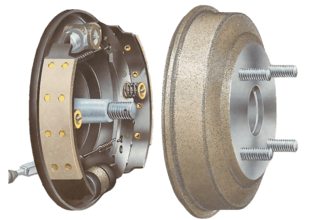

Brake fluid is generally renewed when a leaking or sticking wheel cylinder on a drum brake is re...

Check drum brakes at least every six months, 6,000 miles or 10,000 km, or as recommended in the ...

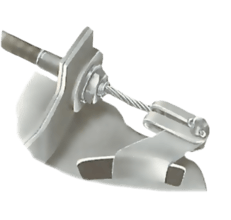

Handbrake cable layouts vary from car to car, but have only a limited range of types of componen...

In a fully sealed cooling system, the cap on top of the radiator is not usually opened for toppin...

The parts of the cooling system most likely to give trouble are water hoses. Age and the movement...

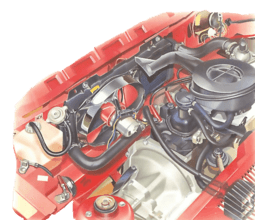

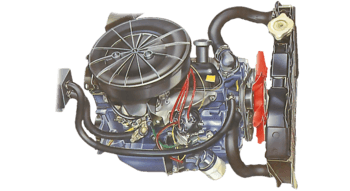

Removing the cylinder head is straightforward on pushrod engines, but more complicated on overhea...

The electrical wiring in a car is a system of colour-coded wires called the loom. Where several w...

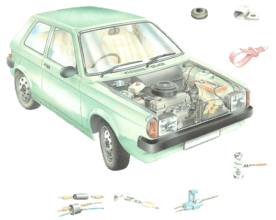

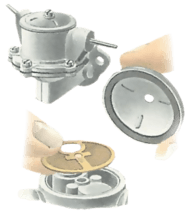

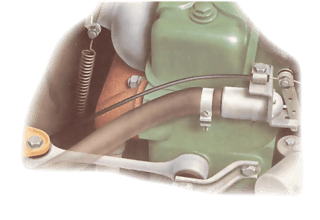

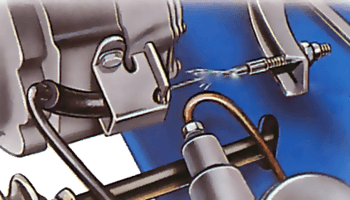

Any fuel leak, however small, can cause a fire. Do not drive a car with a suspected leak until yo...

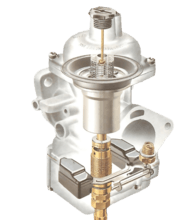

If a car stops and has not run out of petrol, check whether there is petrol in the carburettor....

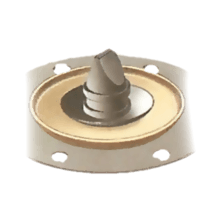

A blocked fuel-pump filter will cause the engine to cut out intermittently, particularly at high...

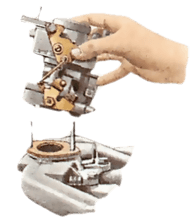

Over a period of time, dirt inevitably gets through the fuel filter of a carburettor, and chemic...

The Stromberg carburettor does not have a regular service schedule, but should be cleaned about ...

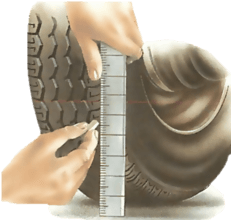

Les roues avant mal alignées peuvent provoquer une usure inégale des pneus et peuvent sérieuseme...

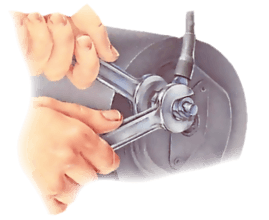

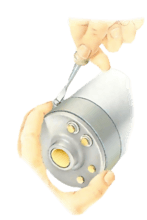

Both inertia and pre-engaged starters can have one of two types of commutator. It may be a cylin...

If a check of the rack gaiters reveals that the rubber is starting to crack, split or perish, rep...

Inspect the ignition system whenever you make a general under-bonnet check. It takes only a coup...

Engines prone to rock on their rubber mountings, particularly at idling speeds, have extra damper...

The clutch cable has a steel-wire inner core sliding inside an outer sheath. It should last at l...

There are two main types of oil seal: static and dynamic. A static oil seal fits between two non...

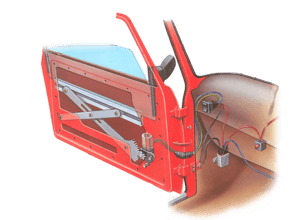

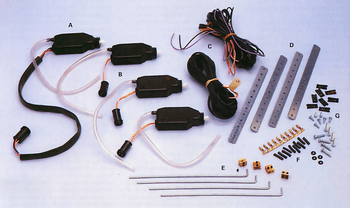

Electric windows are being fitted to more and more cars as standard equipment, while conversion k...

The standard twin-speaker car stereo system has one obvious drawback. If you mount the speakers ...

Car theft or car break-ins are always a worry to the motorist and it is wise to take every...

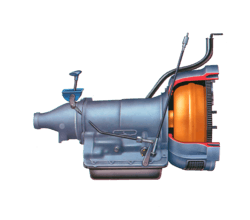

Although they are considerably more complicated than manual gearboxes, with control and operating...

If your car has a cable-operated clutch and you find that the gears are difficult to engage, the...

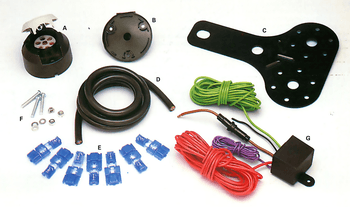

A caravan or trailer must, by law, be fitted with certain warning lights. These are wired up to ...