Tournevis

The best screwdrivers have shafts made from good-quality steel, and handles of tough moulded plastic.

Buy a tool with a reputable brand name. Cheap tools with brittle plastic handles can be dangerous, as they may break under pressure.

Use a screwdriver with a blade that fits exactly into the screw slot - if it is flat-bladed it should be no wider than the slot. If the blade is ill-fitting, the tool is more likely to slip or open out the screw head. Keep flat blades ground square, with the edge evenly tapered.

A very tight screw can sometimes be shocked loose by tapping the end of the screwdriver with a hammer. A few drops of penetrating oil and a firm tap may free a rusted screw.

Engineer's screwdriver

Strong-shafted engineer's screwdrivers are designed for heavy mechanical work. The longer the shaft and the thicker the handle, the greater the turning effort that can be applied.

The blades may be flat to fit into a straight (or plain) slot screw, or cross-headed (such as Phillips or Pozidrive) to fit into a cross-slot screw. Use the correct type of cross-head for the screw, or its slot may be damaged.

Shafts generally range in length from about 100 to 300mm plain, or 80-200mm cross-head. Shafts may be squared or have a hexagonal shoulder at the base so that a spanner can be fitted to help with stubborn screws.

Chubby screwdriver

Short-handled, short-shafted chubby or stubby screwdrivers are designed for use in confined spaces. Some have handles that can be fitted with a T-bar to give extra leverage.

Shafts are generally about 35-38mm long, and both flat-head or cross-head blades are available.

Angle screwdriver

Angle, right-angle or offset screwdrivers are useful for reaching screws in awkward positions. They are generally 5 to 6in. long. Normally, angle screwdrivers have a blade at each end; both may be the same type - flat or cross-head - or there may be one end of each type

A screwdriver is a tool, manual or powered, for turning (driving or removing) screws. A typical simple screwdriver has a handle and a shaft, and a tip that the user inserts into the screw head to turn it. The shaft is usually made of tough steel to resist bending or twisting. The tip may be hardened to resist wear, treated with a dark tip coating for improved visual contrast between tip and screw—or ridged or treated for additional 'grip'. Handle are typically wood, metal, or plastic and usually hexagonal, square, or oval in cross-section to improve grip and prevent the tool from rolling when set down. Some manual screwdrivers have interchangeable tips that fit into a socket on the end of the shaft and are held in mechanically or magnetically. These often have a hollow handle that contains various types and sizes of tips, and a reversible ratchet action that allows multiple full turns without repositioning the tip or the user's hand.

A screwdriver is classified by its tip, which is shaped to fit the driving surfaces—slots, grooves, recesses, etc.—on the corresponding screw head. Proper use requires that the screwdriver's tip engage the head of a screw of the same size and type designation as the screwdriver tip. Screwdriver tips are available in a wide variety of types and sizes (List of screw drives). The two most common are the simple 'blade'-type for slotted screws, and Phillips.

A wide variety of power screwdrivers range from a simple 'stick'-type with batteries, a motor, and a tip holder all inline, to powerful "pistol" type VSR (variable-speed reversible) Cordless drills that also function as screwdrivers. This is particularly useful as drilling a pilot hole before driving a screw is a common operation. Special combination drill-driver bits and adapters let an operator rapidly alternate between the two. Variations include impact drivers, which provide two types of 'hammering' force for improved performance in certain situations, and "right-angle" drivers for use in tight spaces. Many options and enhancements, such as built-in bubble levels, high/low gear selection, magnetic screw holders, adjustable-torque clutches, keyless chucks, 'gyroscopic' control, etc., are available.

Read more on Wikipedia

Cet outil est utilisé dans

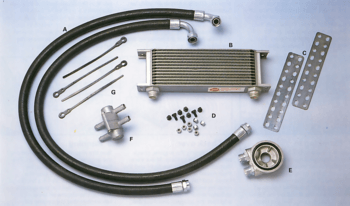

The oil in your engine needs to be kept at an optimum temperature so it can still carry heat...

One of the main reasons why so many cars are stolen is that a thief, even if inexperienced, can...

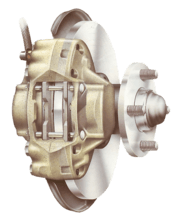

A typical braking system uses disc brakes at the front of the car and drum brakes at the rear....

Les voitures sont généralement équipés d'une haute fréquence (HF) ou d'une corne comme équipemen...

Check the engine oil level weekly more often if the engine is consuming some oil, and always bef...

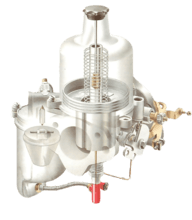

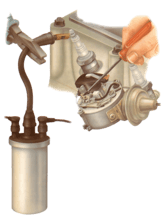

The SU carburettor is simple to strip. It has only one jet (except in a few special types) and...

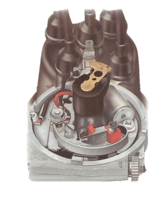

The contact-breaker setting is often neglected, but it is vital to good running. Ideally, check ...

Tyres are put under tremendous strains when a car is being driven. There are only four relativel...

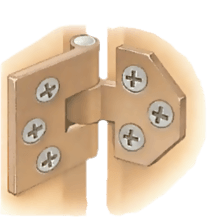

À intervalle d’entretien régulier, nettoyez et lubrifiez les charnières des panneaux mobiles et d...

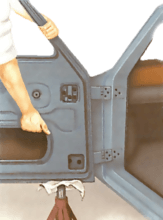

Before a door-trim panel can be removed, the window winder and interior handle must be taken off...

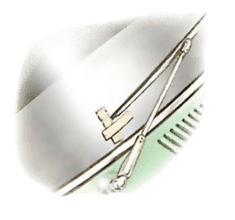

Wiper blades are fitted bayonet-style to the end of the arm, or the end of the arm is hooked...

Fitting a cartridge-type filter Fitting a new disposable cartridge is a simple task, but you mus...

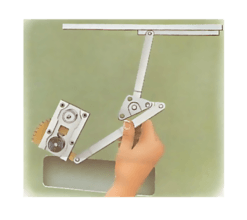

There are three basic systems used to raise and lower car windows: mechanical linkage with sciss...

If your car is misfiring or running badly, or has suddenly stopped completely, the most likely s...

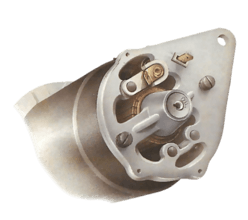

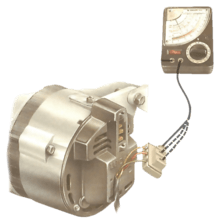

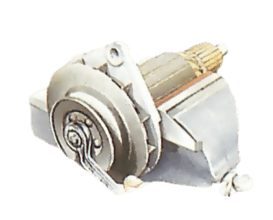

The dynamo is a robust and simple type of generator which was fitted to many earlier cars. Most ...

Doors or bonnet and boot lids that do not close properly may have moved out of alignment and nee...

It is vital to know when disc-brake pads need replacing. Some makers state a minimum safe thickn...

Many hinges are welded to the car bodywork and cannot be adjusted or renewed. But if a door or...

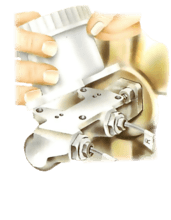

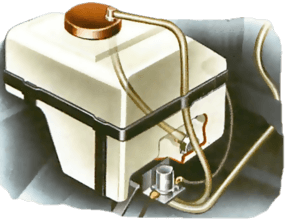

If a master cylinder is leaking replace it. The cylinder is usually mounted on the bulkhead sepa...

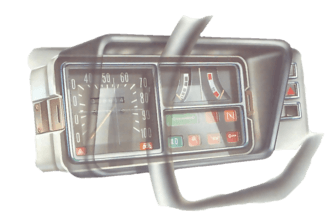

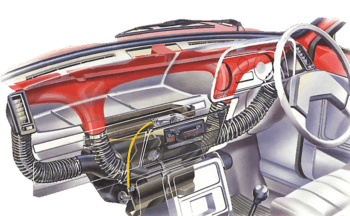

A car usually has up to six main instruments — speedometer and tachometer (rev counter); fuel, o...

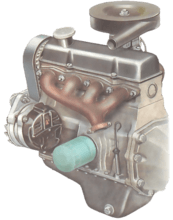

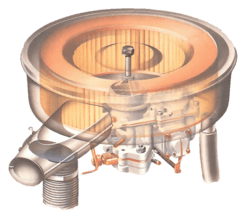

A choked filter in an air cleaner causes increased fuel consumption and, eventually, extra engin...

Cars with electrically operated windscreen washers sometimes have a switch controlling the motor...

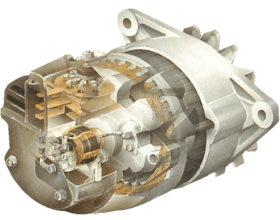

Les alternateurs ont remplacés les dynamos sur les voitures plus récentes, du fait de leurs capa...

When you take the wheels off to inspect the tyre walls, clean the wheels thoroughly and look clo...

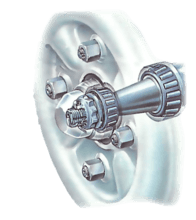

Wheel bearings need periodic checking - and adjusting if necessary - usually at 12,000 mile serv...

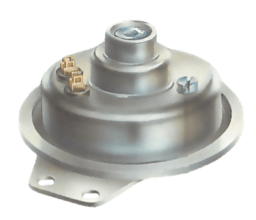

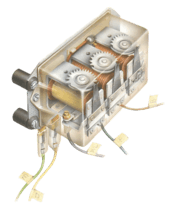

On cars with dynamos, faults in the control box show up in various ways, some of which are descr...

Wear on the carbon brushes and commutator is the most common cause of dynamo failure. Normally t...

When you have tested the charging system of a car fitted with an alternator, and the checks in H...

The most common reason for removing a dynamo pulley is to fit it on a new dynamo — most...

The flow of air into the car can be blocked by leaves or road debris in the supply tubes or...