Tournevis

The best screwdrivers have shafts made from good-quality steel, and handles of tough moulded plastic.

Buy a tool with a reputable brand name. Cheap tools with brittle plastic handles can be dangerous, as they may break under pressure.

Use a screwdriver with a blade that fits exactly into the screw slot - if it is flat-bladed it should be no wider than the slot. If the blade is ill-fitting, the tool is more likely to slip or open out the screw head. Keep flat blades ground square, with the edge evenly tapered.

A very tight screw can sometimes be shocked loose by tapping the end of the screwdriver with a hammer. A few drops of penetrating oil and a firm tap may free a rusted screw.

Engineer's screwdriver

Strong-shafted engineer's screwdrivers are designed for heavy mechanical work. The longer the shaft and the thicker the handle, the greater the turning effort that can be applied.

The blades may be flat to fit into a straight (or plain) slot screw, or cross-headed (such as Phillips or Pozidrive) to fit into a cross-slot screw. Use the correct type of cross-head for the screw, or its slot may be damaged.

Shafts generally range in length from about 100 to 300mm plain, or 80-200mm cross-head. Shafts may be squared or have a hexagonal shoulder at the base so that a spanner can be fitted to help with stubborn screws.

Chubby screwdriver

Short-handled, short-shafted chubby or stubby screwdrivers are designed for use in confined spaces. Some have handles that can be fitted with a T-bar to give extra leverage.

Shafts are generally about 35-38mm long, and both flat-head or cross-head blades are available.

Angle screwdriver

Angle, right-angle or offset screwdrivers are useful for reaching screws in awkward positions. They are generally 5 to 6in. long. Normally, angle screwdrivers have a blade at each end; both may be the same type - flat or cross-head - or there may be one end of each type

A screwdriver is a tool, manual or powered, for turning (driving or removing) screws. A typical simple screwdriver has a handle and a shaft, and a tip that the user inserts into the screw head to turn it. The shaft is usually made of tough steel to resist bending or twisting. The tip may be hardened to resist wear, treated with a dark tip coating for improved visual contrast between tip and screw—or ridged or treated for additional 'grip'. Handle are typically wood, metal, or plastic and usually hexagonal, square, or oval in cross-section to improve grip and prevent the tool from rolling when set down. Some manual screwdrivers have interchangeable tips that fit into a socket on the end of the shaft and are held in mechanically or magnetically. These often have a hollow handle that contains various types and sizes of tips, and a reversible ratchet action that allows multiple full turns without repositioning the tip or the user's hand.

A screwdriver is classified by its tip, which is shaped to fit the driving surfaces—slots, grooves, recesses, etc.—on the corresponding screw head. Proper use requires that the screwdriver's tip engage the head of a screw of the same size and type designation as the screwdriver tip. Screwdriver tips are available in a wide variety of types and sizes (List of screw drives). The two most common are the simple 'blade'-type for slotted screws, and Phillips.

A wide variety of power screwdrivers range from a simple 'stick'-type with batteries, a motor, and a tip holder all inline, to powerful "pistol" type VSR (variable-speed reversible) Cordless drills that also function as screwdrivers. This is particularly useful as drilling a pilot hole before driving a screw is a common operation. Special combination drill-driver bits and adapters let an operator rapidly alternate between the two. Variations include impact drivers, which provide two types of 'hammering' force for improved performance in certain situations, and "right-angle" drivers for use in tight spaces. Many options and enhancements, such as built-in bubble levels, high/low gear selection, magnetic screw holders, adjustable-torque clutches, keyless chucks, 'gyroscopic' control, etc., are available.

Read more on Wikipedia

Cet outil est utilisé dans

Speedometer failure is likely to be caused by a fault in the cable that runs from the gearbox to...

When you have tested the charging system of a car fitted with an alternator, and the checks in H...

In a fully sealed cooling system, the cap on top of the radiator is not usually opened for toppin...

Sealed-beam headlamps are simple to change, but the way of gaining access to them varies from ca...

Anti-pollution laws in many countries now limit the volume of poisonous carbon monoxide gas (CO)...

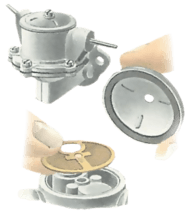

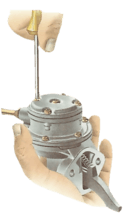

A blocked fuel-pump filter will cause the engine to cut out intermittently, particularly at high...

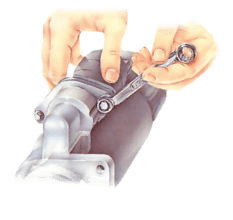

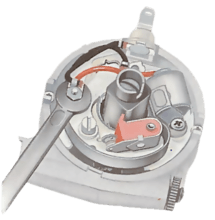

Lors de la pose de nouveaux points de contact dans le distributeur, la façon normale de vérificat...

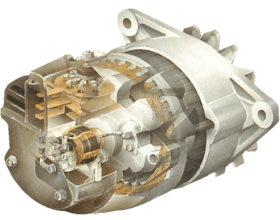

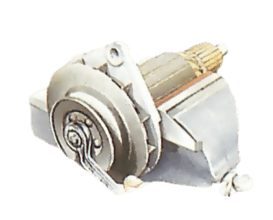

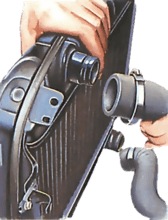

Remove the starter motor from the car (See Checking and replacing starter-motor brushes). The bo...

Places where vital components are mounted on the bodywork or chassis should be inspected at leas...

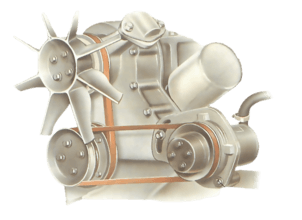

La courroie qui entraîne une pompe de fluide hydraulique de direction est assistée généralement ...

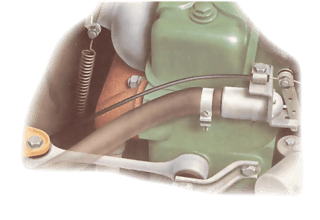

The clutch cable has a steel-wire inner core sliding inside an outer sheath. It should last at l...

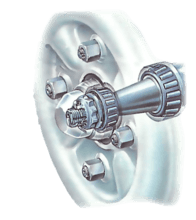

Wheel bearings need periodic checking - and adjusting if necessary - usually at 12,000 mile serv...

When you take the wheels off to inspect the tyre walls, clean the wheels thoroughly and look clo...

There are two main types of oil seal: static and dynamic. A static oil seal fits between two non...

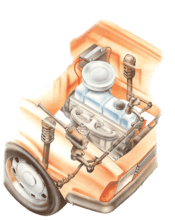

Engines prone to rock on their rubber mountings, particularly at idling speeds, have extra damper...

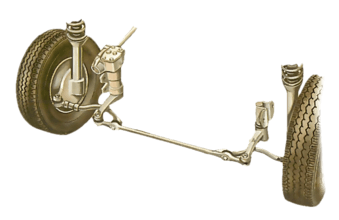

The joints in a steering system all wear gradually and become slack. Because there are so many o...

Starter-motor bearings are usually bushes made of graphite-bronze. A few starters - especially h...

If testing the starter circuit (See Checking the starter circuit) indicates a fault in the starte...

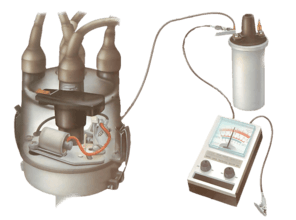

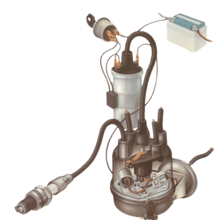

The timing mechanism in the ignition system causes the sparkplug to fire in each cylinder just b...

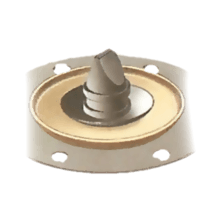

The condenser is a small electrical device connected across the contact-breaker points in the di...

The high-tension leads from the coil to the distributor and from there to the plugs may start to...

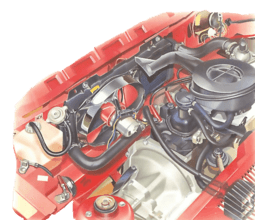

Inspect the ignition system whenever you make a general under-bonnet check. It takes only a coup...

Remove the top of the pump first. It is held on by a central bolt or screw, except on...

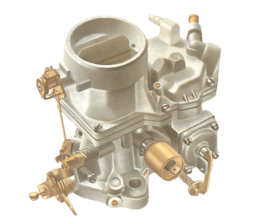

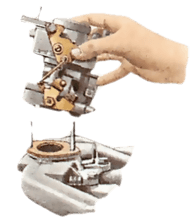

Over a period of time, dirt inevitably gets through the fuel filter of a carburettor, and chemic...

If a car stops and has not run out of petrol, check whether there is petrol in the carburettor....

À intervalle d’entretien régulier, nettoyez et lubrifiez les charnières des panneaux mobiles et d...

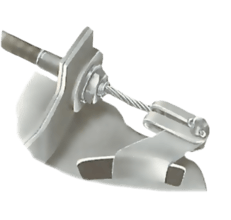

Handbrake cable layouts vary from car to car, but have only a limited range of types of componen...

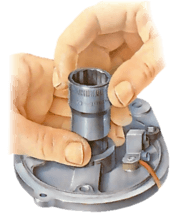

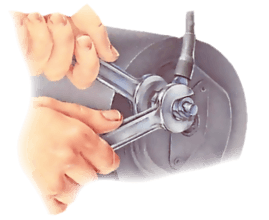

The most common reason for removing a dynamo pulley is to fit it on a new dynamo — most...

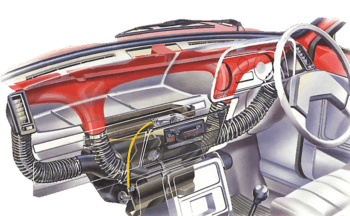

The flow of air into the car can be blocked by leaves or road debris in the supply tubes or...

Sur une période de plusieurs années, des sédiments dans le système de refroidissement d'une voit...