Clés

Good spanners are forged from chrome vanadium. It is not worth buying cheap ones, which are likely to widen under pressure. If you want more than two or three ring or open-ended spanners, it is usually cheaper to buy a set, with probably five or eight spanners of metric, AF or BA sizes.

Most spanners are double ended, with consecutive sizes increasing mainly by 1mm or sixteenths of an inch(AF) at each end. Some spanners have one size duplicated on the spanner of the next consecutive size so that two nuts of the same size can be turned at the same time.

There is no clear distinction between a spanner and a wrench. Different tool catalogues may use either term for the same tool. The word wrench is also sometimes used to describe grips.

Open-ended spanner

Because it does not grip all round a nut, an open-ended spanner is likely to slip and round off the edges of a tight nut unless it is an exact fit.

Where possible, use a ring spanner to loosen a nut, then an open-ended spanner, which is faster to use, to undo it if the nut is still more than finger tight.

Combination spanner

A combination spanner has a ring at one end and is open-ended at the other. Both ends are the same size, so the ring end (Which may be slightly offset) can be used to loosen the nut and the spanner turned to undo the nut faster with the other open end.

Because only one size is covered in each spanner, a set of combination spanners is relatively more expensive than a set of individual ring or open-ended spanners.

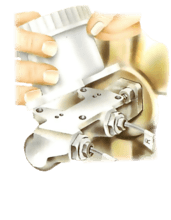

Adjustable spanner

An adjustable spanner is open ended, with one movable jaw that can be screwed in or out to fit a number of nut sizes. Use it only if the correct ring or open-ended spanner is not available.

Buy one that gives a wider opening than your largest ring or open-ended spanner. A 300mm crescent-shaped spanner is likely to have a maximum opening of 34mm. Make sure the jaws fit well together, with no free play or any tendency to rock or back off when pressure is applied.

Unless properly fitted on a nut, the spanner may be strained, or slip and round off the nut edges. Fit the spanner jaws as far on to the nut as possible, and position it so that the main pressure is exerted on the fixed jaw.

A wrench (also called a spanner) is a tool used to provide grip and mechanical advantage in applying torque to turn objects—usually rotary fasteners, such as nuts and bolts—or keep them from turning.

In British English, spanner is the standard term. The most common shapes are called open-ended spanner and ring spanner. The term wrench is generally used for tools that turn non-fastening devices (e.g. tap wrench and pipe wrench), or may be used for a monkey wrench - an adjustable spanner.

In American English, wrench is the standard term. The most common shapes are called open-end wrench and box-end wrench. In American English, spanner refers to a specialized wrench with a series of pins or tabs around the circumference. (These pins or tabs fit into the holes or notches cut into the object to be turned.) In American commerce, such a wrench may be called a spanner wrench to distinguish it from the British sense of spanner.

Higher quality wrenches are typically made from chromium-vanadium alloy tool steels and are often drop-forged. They are frequently chrome-plated to resist corrosion and ease cleaning.

Hinged tools, such as pliers or tongs, are not generally considered wrenches in English, but exceptions are the plumber wrench (pipe wrench in British English) and Mole wrench (sometimes Mole grips in British English).

Read more on Wikipedia

Cet outil est utilisé dans

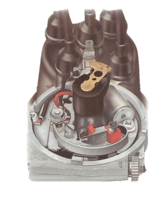

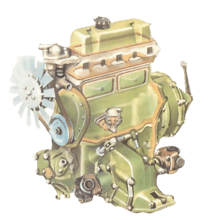

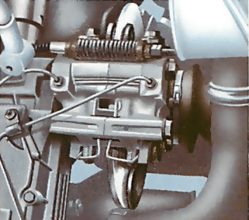

The contact-breaker setting is often neglected, but it is vital to good running. Ideally, check ...

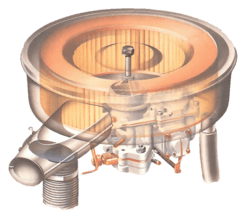

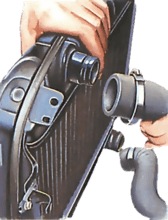

Fitting a cartridge-type filter Fitting a new disposable cartridge is a simple task, but you mus...

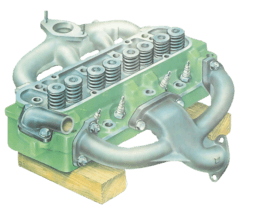

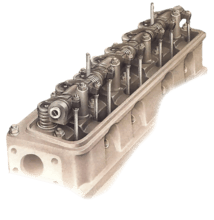

Good engine performance depends on valve condition. Worn guides or stems and burned or badly seat...

If the oil pump is fitted to the outside of the engine, you may be able to reach it...

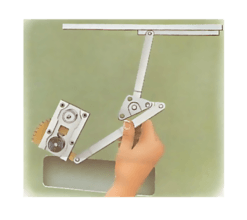

There are three basic systems used to raise and lower car windows: mechanical linkage with sciss...

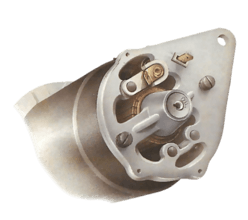

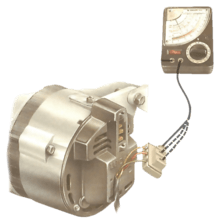

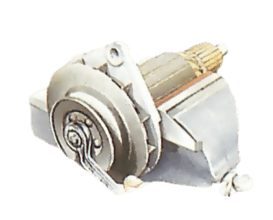

The dynamo is a robust and simple type of generator which was fitted to many earlier cars. Most ...

Doors or bonnet and boot lids that do not close properly may have moved out of alignment and nee...

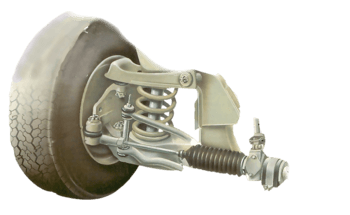

Most modern cars have sealed for life joints in at least part of the steering system. These do no...

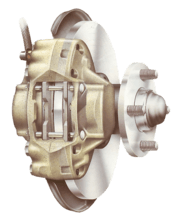

It is vital to know when disc-brake pads need replacing. Some makers state a minimum safe thickn...

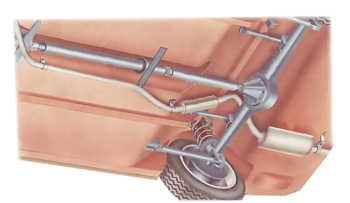

A damaged or worn exhaust system allows waste gases from the engine to escape before they have p...

If a master cylinder is leaking replace it. The cylinder is usually mounted on the bulkhead sepa...

A choked filter in an air cleaner causes increased fuel consumption and, eventually, extra engin...

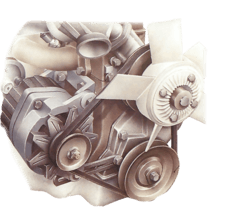

Les courroies d'entraînement s'étirent toujours un peu en cours d'utilisation, en raison des con...

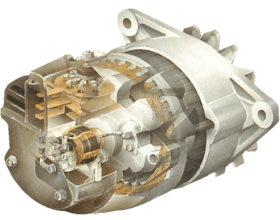

Les alternateurs ont remplacés les dynamos sur les voitures plus récentes, du fait de leurs capa...

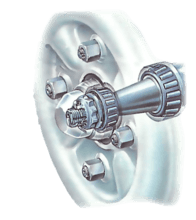

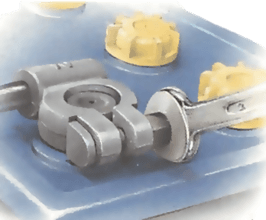

Wheel bearings need periodic checking - and adjusting if necessary - usually at 12,000 mile serv...

When you have tested the charging system of a car fitted with an alternator, and the checks in H...

The most common reason for removing a dynamo pulley is to fit it on a new dynamo — most...

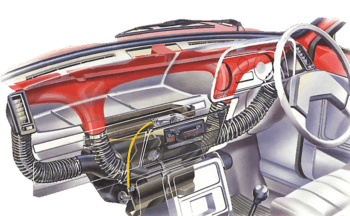

The flow of air into the car can be blocked by leaves or road debris in the supply tubes or...

Sur une période de plusieurs années, des sédiments dans le système de refroidissement d'une voit...

Sealed-beam headlamps are simple to change, but the way of gaining access to them varies from ca...

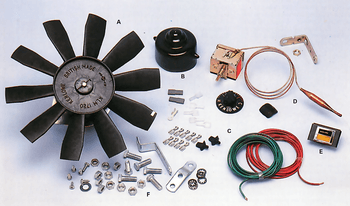

Les moteurs électriques des ventilateurs sont allumés soit par le commutateur d'allumage - et co...

Si un moteur à besoin de rajouter de l'huile fraîche plus que d'habitude, ou si vous voyez une f...

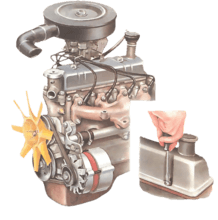

Fitting an electric, thermostatically controlled fan in place of the mechanical, engine-driven t...

Des interférences radio du véhicule proviennent habituellement du système d'allumage, du circuit...

Le jeu des soupapes ont des petits espaces entre les sommets des tiges de soupape et la partie d...

Gaskets and oil seals should be replaced if worn or leaking, or whenever removed during servicin...

Windscreen washers and wipers must, by law, be in working order. Keep the washer bottle topped u...

If you have tightened the brake shoes so that there is no excess travel before they come on, yet...

A spongy feel or increased pedal travel as you apply the footbrake could indicate a leak or air ...

Un léger clic ou un silence total lorsque la clé du démarreur est mis généralement signifie que ...