Clés

Good spanners are forged from chrome vanadium. It is not worth buying cheap ones, which are likely to widen under pressure. If you want more than two or three ring or open-ended spanners, it is usually cheaper to buy a set, with probably five or eight spanners of metric, AF or BA sizes.

Most spanners are double ended, with consecutive sizes increasing mainly by 1mm or sixteenths of an inch(AF) at each end. Some spanners have one size duplicated on the spanner of the next consecutive size so that two nuts of the same size can be turned at the same time.

There is no clear distinction between a spanner and a wrench. Different tool catalogues may use either term for the same tool. The word wrench is also sometimes used to describe grips.

Open-ended spanner

Because it does not grip all round a nut, an open-ended spanner is likely to slip and round off the edges of a tight nut unless it is an exact fit.

Where possible, use a ring spanner to loosen a nut, then an open-ended spanner, which is faster to use, to undo it if the nut is still more than finger tight.

Combination spanner

A combination spanner has a ring at one end and is open-ended at the other. Both ends are the same size, so the ring end (Which may be slightly offset) can be used to loosen the nut and the spanner turned to undo the nut faster with the other open end.

Because only one size is covered in each spanner, a set of combination spanners is relatively more expensive than a set of individual ring or open-ended spanners.

Adjustable spanner

An adjustable spanner is open ended, with one movable jaw that can be screwed in or out to fit a number of nut sizes. Use it only if the correct ring or open-ended spanner is not available.

Buy one that gives a wider opening than your largest ring or open-ended spanner. A 300mm crescent-shaped spanner is likely to have a maximum opening of 34mm. Make sure the jaws fit well together, with no free play or any tendency to rock or back off when pressure is applied.

Unless properly fitted on a nut, the spanner may be strained, or slip and round off the nut edges. Fit the spanner jaws as far on to the nut as possible, and position it so that the main pressure is exerted on the fixed jaw.

A wrench (also called a spanner) is a tool used to provide grip and mechanical advantage in applying torque to turn objects—usually rotary fasteners, such as nuts and bolts—or keep them from turning.

In British English, spanner is the standard term. The most common shapes are called open-ended spanner and ring spanner. The term wrench is generally used for tools that turn non-fastening devices (e.g. tap wrench and pipe wrench), or may be used for a monkey wrench - an adjustable spanner.

In American English, wrench is the standard term. The most common shapes are called open-end wrench and box-end wrench. In American English, spanner refers to a specialized wrench with a series of pins or tabs around the circumference. (These pins or tabs fit into the holes or notches cut into the object to be turned.) In American commerce, such a wrench may be called a spanner wrench to distinguish it from the British sense of spanner.

Higher quality wrenches are typically made from chromium-vanadium alloy tool steels and are often drop-forged. They are frequently chrome-plated to resist corrosion and ease cleaning.

Hinged tools, such as pliers or tongs, are not generally considered wrenches in English, but exceptions are the plumber wrench (pipe wrench in British English) and Mole wrench (sometimes Mole grips in British English).

Read more on Wikipedia

Cet outil est utilisé dans

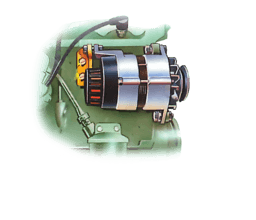

Alternators are powerful enough to cope with the demand for current made by a modern car's electr...

If your car has a cable-operated clutch and you find that the gears are difficult to engage, the...

Running-on is when the engine continues to turn after you've switched off the ignition because th...

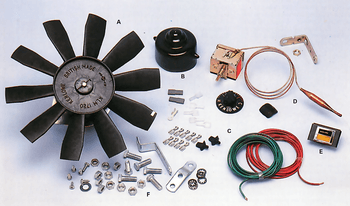

Fitting an electric, thermostatically controlled fan in place of the mechanical, engine-driven t...

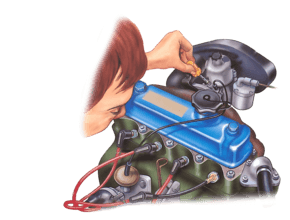

Although some experienced mechanics can tune a car's carburettor fairly well by ear, to do the j...

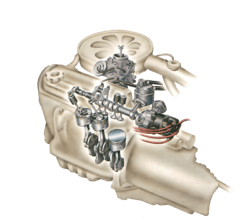

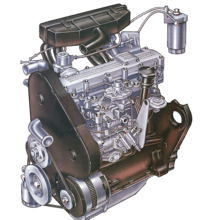

In many ways a diesel engine is less complicated than a petrol engine, with greater reliability ...

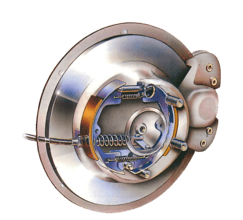

Most cars are still fitted with drums on the back wheels with the handbrake operating directly o...

Quarterlights are now rarely fitted by manufacturers so you mostly find them on older cars. It i...

One way of changing your car's appearance is to fit a front or rear spoiler. These can also redu...

The front wheels on most cars are not set exactly parallel. Instead they point slightly in or sl...

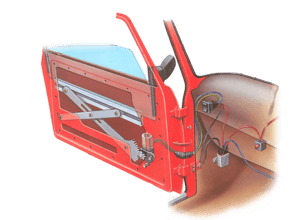

Electric windows are being fitted to more and more cars as standard equipment, while conversion k...

Many modern cars are now designed so that their lights are built as a one-piece unit known as a c...

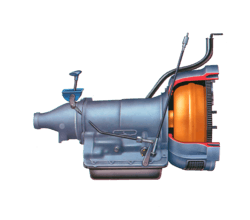

Although they are considerably more complicated than manual gearboxes, with control and operating...

The majority of indicator stalks are mounted on the side of the steering column so you can easil...

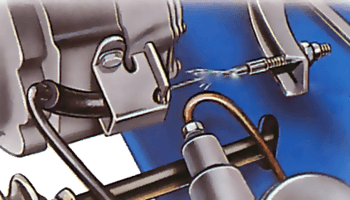

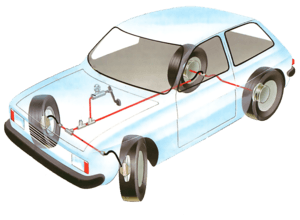

Checking the condition of your car's brake pipes is a job that is all too easy to forget because...

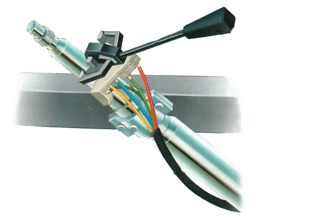

The fluid in the car's braking system runs from the master cylinder to the brakes themselves mai...

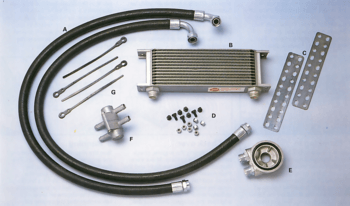

The oil in your engine needs to be kept at an optimum temperature so it can still carry heat...