Vous pourriez avoir besoin de

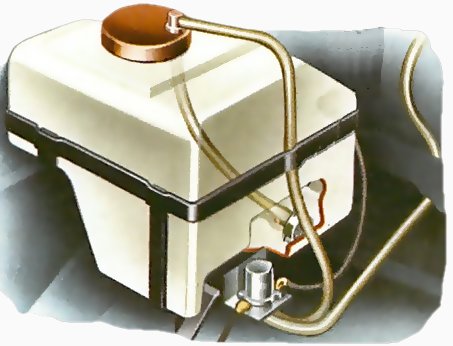

On current models the motor and impeller unit fits on top of the washer container.

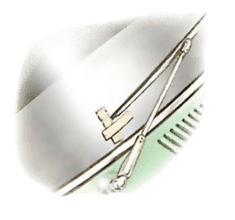

Cars with electrically operated windscreen washers sometimes have a switch controlling the motor incorporated within the windscreen-wiper switch. If the motor does not work, check first that the switch is functioning; if it is, check the wiring to the washer motor (See How to test electrical circuits).

If electrical power is reaching the washer motor but it still refuses to work, the fault may be a poor earth return, corroded terminals, dirty or damaged wiring, or the motor may be too tight in its mounting.

Check all these items and rectify them as necessary (See Working on the wiring system). If the motor still refuses to work, it must be replaced. Fit a new non-return valve in the reservoir when renewing the motor.

This video course is the best way to learn everything about cars.

Three hours of instruction available right now, and many more hours in production.

- 4K HD with full subtitles

- Complete disassembly of a sports car

A motor replacement kit can be bought from an accessory shop. Alternatively, you may be able to buy an exact washer motor replacement unit from the local dealer for your make of car.

Some motors are separate from the reservoir but fitted close by. Others are combined with the reservoir. If you buy an exact replacement, it will match the existing fittings and can be fitted in place of the old one without any alterations to the mounting or connections.

If you have to fit a new motor of a different pattern, you can probably leave the old motor in position and bypass it, fitting the new one close by in a new mounting. You may have to lengthen the hoses and wiring in order to reach the new motor.

If replacing a different type of motor is not practicable, the whole washer assembly will have to be replaced. Make sure it is the correct type for your car.

Fitting a separate motor of a different pattern

The motor and the pump are usually a single unit, the pump being a simple device. If the non-return valve and the hoses are sound, the old motor can simply be bypassed.

Disconnect the battery. Remove the wiring from the old motor.

Leave the old motor and its inlet pipe in position, and disconnect the water outlet pipe. Plug the outlet stub of the old motor - a brass woodscrew is an ideal plug.

Decide on the location for the new motor. Make sure there is nothing behind the panel where you intend to drill screw holes.

Drill holes (See Drilling holes in car bodywork) for the self-tapping screws provided for the motor mountings. Hold the bracket and motor in position, and fix it in place.

The new motor is mounted near by, and the old one left where it is. You may, however, have to length both the hoses and the electrical wiring to the motor to reach its new position.

The two stubs for the water pipes on the new motor are usually marked with arrows indicating the direction of water flow. Connect the detached outlet pipe to the outlet stub.

In place of the old inlet pipe, fit a length of suction pipe from the new motor to the reservoir. Connect one end to the inlet stub on the motor, and fit the other into the reservoir.

On some reservoir-motor assemblies, you may be able to utilise part of the existing fitting. On others you will have to drill a new hole in the top of the reservoir.

Make sure there is a non-return valve and filter at the bottom end of the pipe in the reservoir.

Check that the reservoir and valve are clean.

Connect the wiring to the motor. If the car has a negative [-] earth, connect the negative terminal of the motor to the car bodywork. If the earthing is positive [+] connect the positive terminal to the bodywork.

Reconnect the battery, switch on the ignition, and operate the washers to test the system.

Fitting a new system on the old bottle

Use a drill bit no bigger than necessary. Or use a smaller bit and open up the hold with a round file until it is just large enough to take the new tube. If necessary, take off the container and shake out any drilling or filing debris that has dropped inside and could block the filter on non-return valve later.

If you have to replace the filter and non-return valve, as well as the motor, it is easy to drill a hole in the top of the plastic container.

Use a drill bit the right size for the new tube, so that the hole is no bigger than necessary.

Whenever you are servicing the washer system, check the filter and the non-return valve to see that they are free of dirt and sediment. Make sure also that there is no dirt or debris in the bottom of the container.

Remove the multi-connector plug from the leads and refit them to the new motor with push-on terminals. Plug the outlet stub of the old motor - a brass woodscrew makes an ideal plug.

Use a drill bit no bigger than necessary. Or use a small bit and open up the hole with a round file until it is just large enough to take the new tube. If necessary, take off the container and shake out any drilling or filing debris that has dropped inside and could block the filter or non-return valve later.

Remove the multiconnector plug from the leads and refit them to the new motor with push-on terminals. Plug the outlet stub of the old motor - a brass woodscrew makes an ideal plug.

Repairing a washer unit on a current model

On current models the motor and impeller unit fits on top of the washer container.

If the windscreen-washer system in your car is a current model, the motor and the impeller assembly can each be removed and replaced, at a relatively low cost.

But obtaining individual parts or making a repair can prove difficult. It is often easier to buy a complete replacement unit from a dealer.