Vis

A vice that bolts or clamps to a workshop bench is a necessity for many repair jobs. Ideally, use a mechanic's (or engineer's) vice, which has close fitting jaws that are grooved for gripping pipes. Jaw openings generally vary from 75-150mm.

Jaw pads of softer material can be obtained; they prevent damage to components, but still hold them in a firm grip. Otherwise, pad the vice jaws with wood.

A vise (American) or vice (British) is a mechanical apparatus used to secure an object to allow work to be performed on it. Vises have two parallel jaws, one fixed and the other movable, threaded in and out by a screw and lever.

Read more on Wikipedia

Cet outil est utilisé dans

Wear on the carbon brushes and commutator is the most common cause of dynamo failure. Normally t...

Modern telescopic dampers cannot be overhauled at home. The only servicing possible is to replac...

The forces imposed on the anti-roll bar subject it to constant twisting and flexing, which in tu...

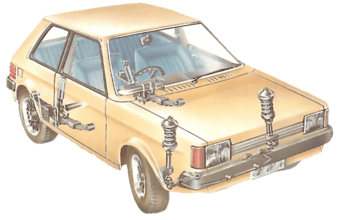

Almost all modern cars have hydraulic telescopic dampers in their suspension systems. Where the ...

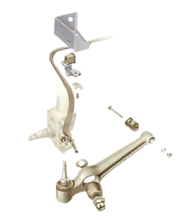

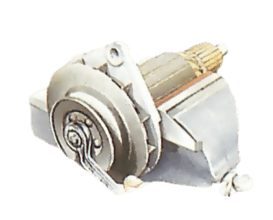

The name Bendix gear strictly applies to the spiral drive mechanism of an inertia-type starter. H...

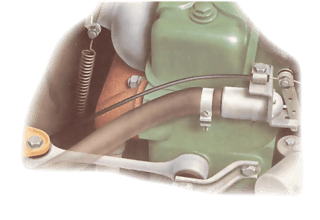

Engines prone to rock on their rubber mountings, particularly at idling speeds, have extra damper...

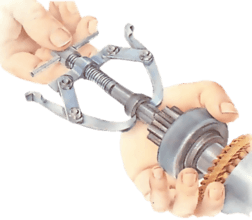

Starter-motor bearings are usually bushes made of graphite-bronze. A few starters - especially h...

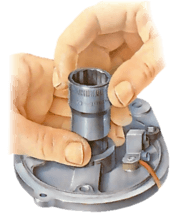

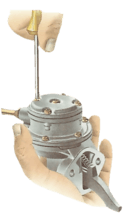

Remove the top of the pump first. It is held on by a central bolt or screw, except on...

À intervalle d’entretien régulier, nettoyez et lubrifiez les charnières des panneaux mobiles et d...

The most common reason for removing a dynamo pulley is to fit it on a new dynamo — most...