Vous pourriez avoir besoin de

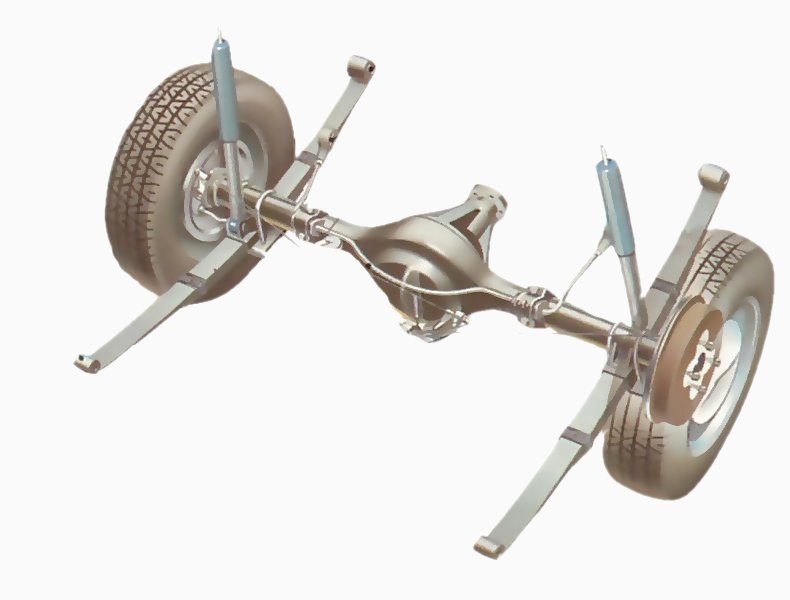

Leaf-spring suspension

Leaf springs are used at the rear in many cars.

Leaf springs are likely to wear because they have several moving parts. They should be inspected at intervals specified by the car manufacturer, or at major service intervals - usually every 12,000 miles (20,000 km).

Before you jack the car up, put it on level ground, make sure that the tyres are at their normal pressures and that the car is at its normal 'kerb weight' without passengers, and with a full fuel tank.

Crouch down a little distance behind the car and see how it sits on the road.

This video course is the best way to learn everything about cars.

Three hours of instruction available right now, and many more hours in production.

- 4K HD with full subtitles

- Complete disassembly of a sports car

It should appear level from side to side. If one side appears lower than the other, there may be a weak or damaged spring on that side.

Prolonged use of the car with only the driver on board may cause a slight sag in the springs on that side of the vehicle. If the sag is significant, the springs may need to be replaced.

Measure ride height from the axle centre-line to the top of the wheel arch.

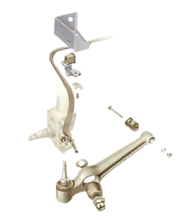

Move to each side of the car and examine the attitude of the swinging link spring shackles, which may be at the front or rear end of the springs. The links should generally be vertical when the vehicle is at its kerb weight.

Any significant deflection to front or rear indicates a weakened spring.

Compare the deflection of the shackles on both sides of the car; they should be approximately the same.

If, from this check, the rear spring or springs appear to be weak, make a further inspection to find the reason. It may be due to damage, or to a general settling down of the springs through age.

Cleaning leaf springs

The standard leaf spring is made from several thin strips of sprung steel of different lengths and held together by clamps.

It is subject to wear as the leaves rub against each other during suspension movement. To overcome this, a tapered-profile single leaf spring is fitted on some vehicles.

Dirt particles between separate leaves accentuate wear and rust. The springs should be kept fairly clean in order to extend their useful life.

The intervals at which this is done will be given in your car handbook.

Modern leaf springs do not need lubricating with oil — which may damage any anti-friction material between leaves. Spray them instead with a silicone-based lubricant.

With most modern cars, leaf springs are found mainly in the rear suspension. Raise the end of the car to clean them.

When working on springs, support the car on chassis members forward of the axle, but not under it.

Remove the hub caps and trims from the wheels, and loosen the wheel nuts. Jack up one side of the car so that the wheel is clear of the ground, and support the car on an axle stand under a chassis member (not under the axle).

Do the same at the other side of the car, so that it is supported under the chassis on both sides, with the wheels clear of the ground.

Wire-brush as much dirt and rust as possible off the spring, especially between the open ends of the leaves.

Chock the front wheels and remove both rear wheels.

The weight of the vehicle is now off the springs, which allows the leaves to separate slightly, making it easier to clean them.

If the spring leaves are really caked with dirt and grease, cleaning them is a messy job.

Clean shackles and bushes thoroughly with a wire brush.

The road or garage floor under the car will be badly stained unless you spread plenty of newspaper or plastic sheeting to catch the drips.

Use a proprietary degreasing fluid if necessary, either spraying it on or using an old scrubbing brush. Dry the springs afterwards with absorbent rags.

Use a proprietary degreaser, applied with a brush or spray, to help remove as much dirt as possible.

If the spring is simply coated with dry dirt or rust, use a wire brush to remove all traces.

Wear safety glasses or goggles to prevent small particles of grit or rust being flicked into your eyes.

Work the brush vigorously along the sides of the spring, the under and upper surfaces and around any clips that may be fitted to hold the leaves together. Afterwards, wipe it clean with a rag.

After cleaning the springs, lubricate them lightly with silicone lubricant, replace both wheels and their wheel nuts. Lower the car to the ground and fully tighten the wheel nuts.

Replace the hub caps and trims, making sure that they are securely located.

Checking leaf springs and mountings

Carry out the checks while the springs are being cleaned (See Cleaning and checking leaf springs).

Look to see if one spring is flatter than the other, in which case the car will probably have a pronounced tilt to one side. This will indicate that you should also check the ride height (See Cleaning and checking leaf springs)

Examine the edges of the spring leaves, look for cracks. Fractures found in the spring leaves cannot be repaired by welding. The leaf or the complete spring must be replaced as soon as possible by a garage. Look at the lower surfaces of the leaves, where the ends of the shorter leaves bear against those above. The tips of the shorter leaf may dip into the surface of the leaf above it, and make a slight depression. The leaves then bind as they move against each other. A slight depression is acceptable, but the spring should be replaced if the depression exceeds a in. (3 mm).

Check the condition of the shackle pins that pass through the rubber bushes. Make sure that they are not bent or badly corroded, in which case they may be very difficult to remove and should be replaced at a garage.

If U-clamps need tightening, check leaves to see if they have moved sideways. If they have, tap them back with a soft-faced hammer.

Make sure the nuts on the U-bolts which hold the springs to the axle are tight. If they are loose, the axle will move in relation to the springs. That will cause steering and tyre wear problems. It will also cause the brakes to judder on application.

The spring centre-bolt head or the dowel pin that locates the spring on its mounting pad may also shear.

The axle is then free to move backwards, and may break away from the springs.

A multi-leaf spring has two or more U-shaped clips towards the outer ends. They hold the main leaves in alignment with each other, and may be held in place by rivets or bolts.

Check the condition and security of each clip. If you find one loose or broken, have it replaced immediately.

Otherwise the spring loading will not be evenly distributed during the full suspension travel over uneven ground. This could cause the master leaf to break under stress.

In some cases, the lower, shorter leaves of the spring are not held in place by spring clips, but rely instead on the U-bolts to keep them in line with the rest of the spring.

Tighten the nuts on the U-bolts that clamp the springs to the axle if they have become loose.

If the U-bolts become slack, the shorter leaves may move sideways. If they do, tap them back into place with a soft-faced hammer and tighten the U-bolt nuts fully.

To check the rubber bushes in the eyes at each end of the springs, back the rear of the car up on ramps. Apply the handbrake firmly and chock the front wheels.

Get under the car and wipe clean the areas around the bushes. Clean also as much of the bushes as the spring shackles allow.

Inspect each bush for signs of wear or distortion caused by the weight of the vehicle on the suspension. See if the rubber has perished, cracked or been contaminated by oil.

If the bushes are damaged, they must be replaced at a garage, as replacement requires removal of the spring from the car and the use of a hydraulic press.

Checking for slackness and rust

With the weight off the axles, try to lever the bushes from side-to-side. The springs should not move.

Take the weight of the car off the suspension to check the springs for sideways movement.

Remove the chocks from the front wheels and drive the car off the ramps. Jack up the back and support each side with an axle stand placed under a firm part of the chassis, not under the axle.

Grasp the spring and try to twist it sideways at each end; it should not move. Check further by trying to lever the bushes from side to side.

If the rubber bush is in good condition, there should be no sideways movement of the spring. If there is, have the bush replaced.

Use a wire brush to clean the grime from around the spring mountings in the floor pan of the car and the shackle bolts.

Check shackle bolts for tightness using socket or ring spanners.

Check each shackle bolt and nut for tightness, and tighten any that are slack.

Take the opportunity to look for signs of corrosion on the floor pan and chassis member around the mountings.

Probe suspect areas with a screwdriver or tap them with a hammer. The metal should be completely sound.

If you find the floor pan or mounting areas to be rusting badly, take the car to a garage for repair. Do not use it for any other journey until this weakness has been fixed.

If there is only surface rust, use a wire brush to clean the metal. Treat the affected area with a proprietary rust preventative, followed by an underbody sealant.

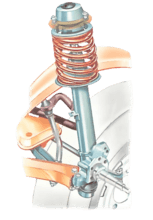

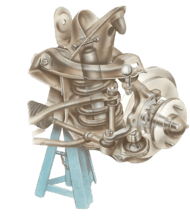

Checking a transverse leaf spring for wear

A few older small cars have a single transverse leaf spring - this is a front one.