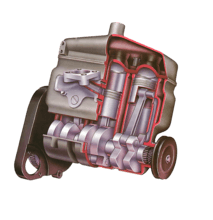

A two-stroke engine

Désolé, nous avons pas encore traduit cette page en français. Nous y travaillons.

Most two-stroke engines are of the crankcase compression type. The fuel/ air mixture is fed into the crankcase through the side of the piston from an inlet manifold mounted low down on the cylinder. The mixture is slightly compressed in the crankcase then transferred to the top of the cylinders, compressed and ignited so that the burning gases expand to drive the pistons down.

Lubricating oil is mixed with the fuel or injected separately. Because the crankshaft bearings are not pressure-fed with oil, they are of the ball or needle-roller bearing type which can operate in an oil mist.

Il apparaît dans

How a two-stroke engine works

Almost all car engines work on the four-stroke cycle, so called because it takes four strokes of ...